Welcome

We are a young company in the field of racing items for motorcycles. Our main products are exhaust and braking systems as well as additive manufactured components for all vehicle categories. Furthermore, we construct and develop special machines for general use mechanical engineering and provide support in the implementation of research projects.

exhaust systems

braking systems

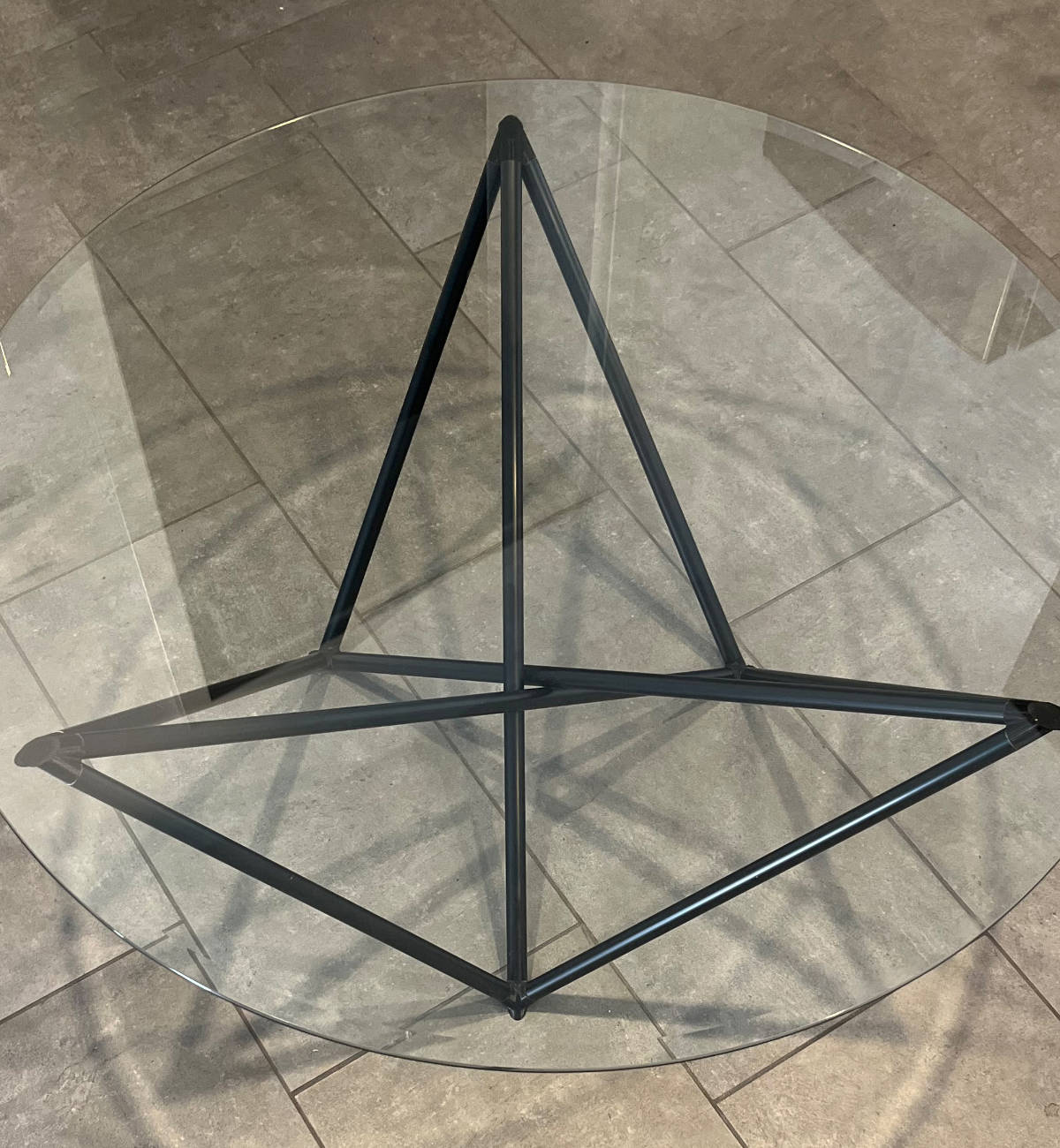

special machines

research projects

Services

Our comprehensive machine park in our own technical center enables us to offer the following services as wage work.

Welding

TIG, MSG and resistance welding of steel, aluminum and special materials such as Titanium. In addition to joint welding, we also offer armouring, build-up welding and solder on. Guarantee professional after-treatment of the welded and soldered joints.

Reshape

Forming of metallic materials using a 15 t and 100 t press. To the manufacturing processes include die bending, swivel bending, 3 roll bending, rubber pad forming and deep drawing

Machining

Whether prototypes, individual parts, small and large series - thanks to the latest CNC lathes and milling machines we produce and deliver precise components and can assemble assemblies. Our manufacturing is specialized in metallic materials and plastic.

Additive manufacturing “3D printing”

Our 3D printer can produce plastic components with the dimensions 300x300x350 [mm] in FDM manufacture procedures. We process PLA, TPU and can rework the components. (thread inserts, surface roughness, machining of functional surfaces)

Research and Development

We support the implementation and application of research projects. In addition to development of the project idea, we can fall back on a large network of project partners which increase the chances of success for your project and the associated product.

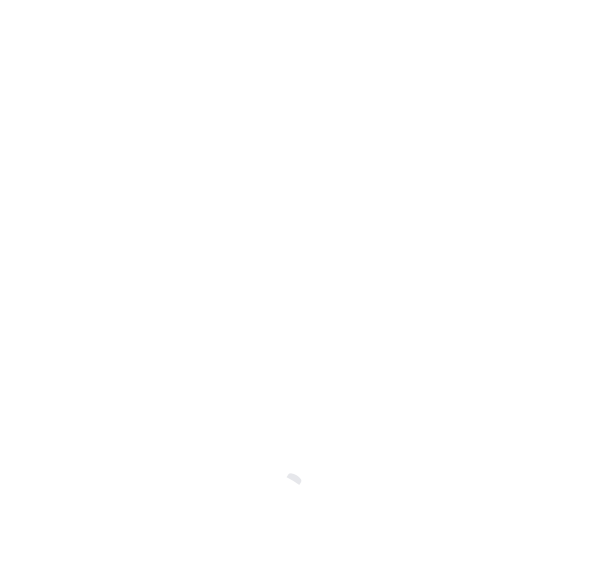

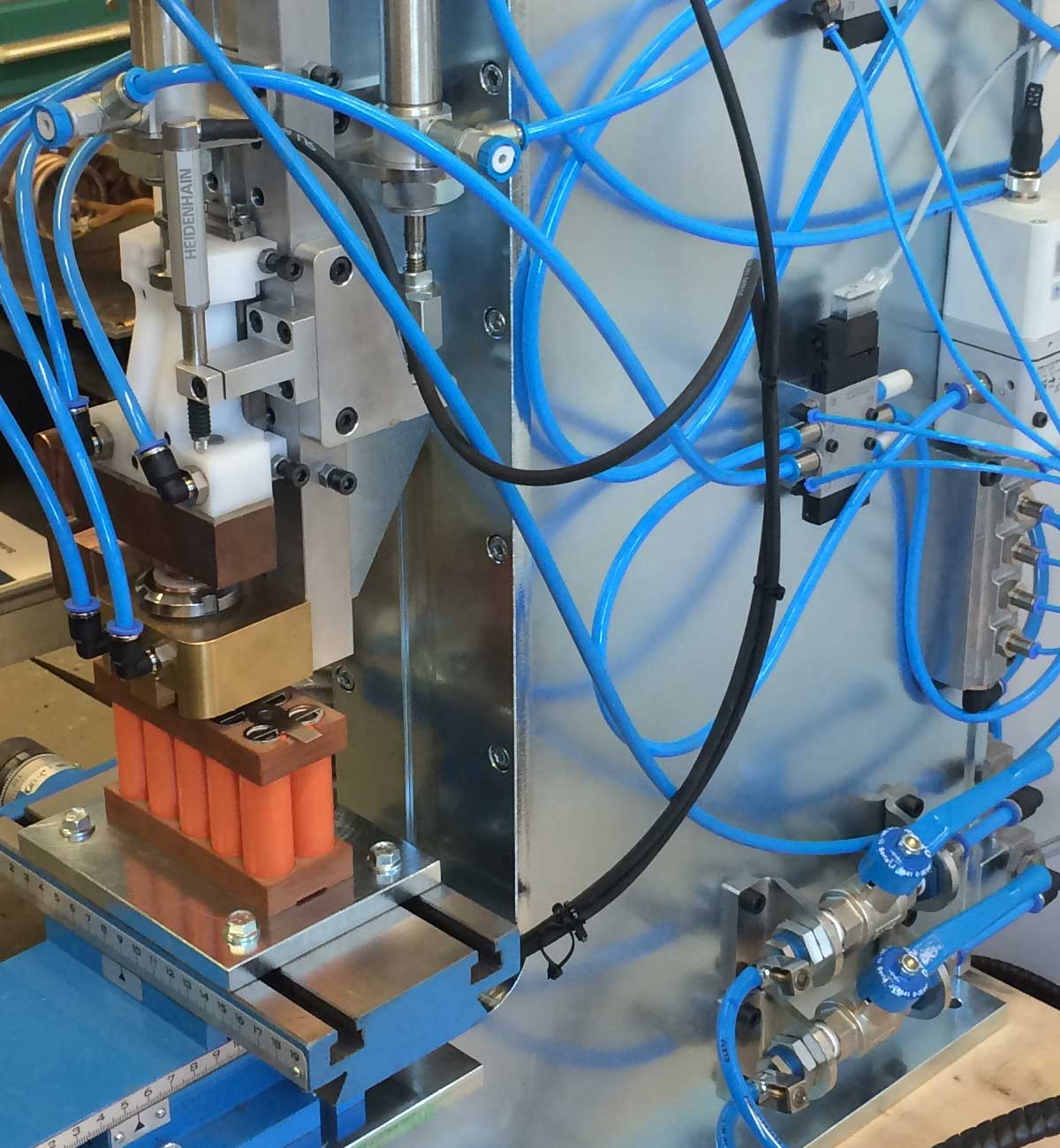

Special mechanical engineering

Partially mechanized special machines for joining and forming metallic materials are our specialty. From the first draft, through the construction to the ready-to-use machine, we can provide the complete cover development and manufacturing process.